What To Do When Your Water Well Begins To Pump Sand Or Grit

Sand in water can lead to abrasive wear of the well pump, clogging, and premature replacement of fixtures, appliances, and your water treatment system.

In private well water systems, often, what appears to be sand can actually be sediment or other particulate material from various sources.

Be sure to determine if what you are observing is coming from your well or within your home, and try to run the water directly from the well into a white bucket to see if you can identify some sand or sediment.

Consider getting your water tested for contaminants, especially if there is a foul odor, bad smell, or taste present.

There are many causes for the sudden appearance of sand in your water well. When your well begins to pump sand, it is usually best to seek advice from a well-driller or pump-contractor to determine the source or cause.

Nonetheless, let's discuss some of the most common causes of sand or grit in your water well and our knowledge on approaching the problem.

Common Causes of Sand and Sediment in Well Water

Well Pump is Set Too Low in Well

If your well suddenly starts to pump sand and sediment, this may indicate that the well is filling with sand or your pump is sitting too low in the well near the bottom of the well.

Most wells use submersible pumps that are down in the water in a casing.

Typically, the well pump is set, so it’s at a minimum of 10 – 20 feet higher than the well's base. But if the pump is down near the well's base, sand or grit and sediment can be drawn in.

In old wells, the well shaft can fill up with fine sand and silt so much that the pump may start to suck in sand from this build-up.

Well Screen Degraded

When the well is drilled, it is lined with steel, iron, or PVC plastic called a casing. The well driller installs the casing in the well shaft.

The well casing has grooves that allow water to penetrate the well from the surrounding groundwater and at the same time keep out sand and grit. This is called the well screen.

Your submersible well pump is down inside this casing, and over time, the good screen can become degraded or corroded, allowing silt and sands to get into the well and pumped into your water system.

Well Pump is Too Large

In some cases, the well pump can be too powerful or strong for the well and consequently pulls sand in from the surrounding aquifer.

This sand can cause a rapid deterioration in the pump's valves and cause a build-up of sand at the bottom of the well, which can lead to sand in your water lines.

In any case, a sudden presence of sand or grit is not a good symptom, and the source or cause should be inspected.

What Should I Do? How to Clean Sand out of Water Well?

If your water well begins to pump sand or sediment, it is often best to contact your well driller or local well professional to discuss the problem and possible ways to fix it.

Sometimes the well contractor can pull up the pump 10 to 20 feet to eliminate sand uptake. A well professional can put a camera down your well and inspect the well screen to see if it has deteriorated or needs repair.

New Well Casing

New Well Casing

In some serious situations, a new casing may be advised.

However, there are also special screens a well contractor can install over the pump to keep out sand.

Although these are not feasible for some wells if the casing is very old or if the well's diameter is too small if it is not feasible or possible to repair, a new well may be recommended.

(Click here if you want to learn more about Groundwater Wells. )

Centrifugal Sand Separator

Another solution is to install a centrifugal sand separator on top of the ground before the pressure tank to filter the water before it enters your home plumbing system. Centrifugal sand separators effectively remove over 98% of all 200 mesh-sized particles (74 microns) and greater.

These sand separators act as filters to remove sand and sediment through centrifugal force, sling large particles, sand, debris, and sludge outward to the separator wall, and downward by the gravitational force pulls the separated solid particles past the spin trap plate into the solids holding chamber.

Cleaned water then rises through the vortex locator and returns to the plumbing system. Once in the solids-holding chamber, the sand can be easily drained out through a small ball valve opening at the bottom of the device, manually or automatically with an auto flush valve.

For most residential and irrigation needs, we recommend the Lakos Sandmaster, and for larger systems or applications up to 290 GPM, we recommend the industrial Lakos Separators.

Filter Screen with Flush Valve

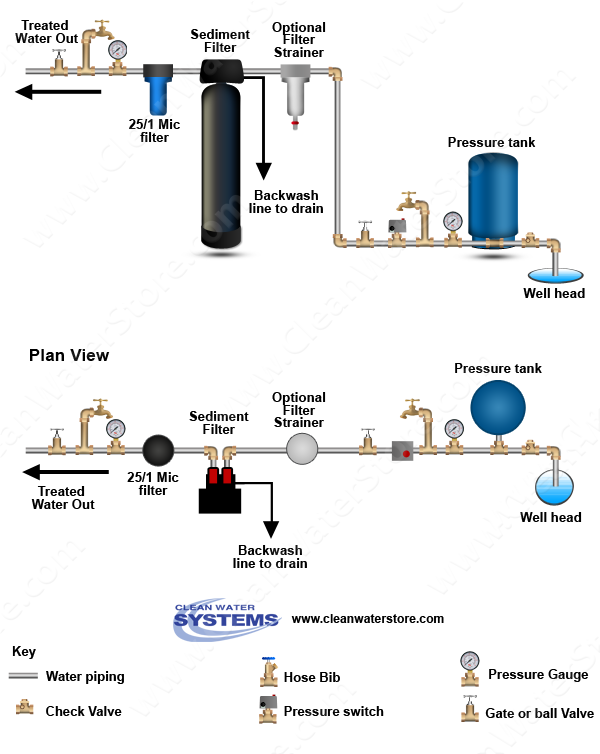

These sand and sediment filters must not be too fine because they can result in a pressure drop. Generally, a 60 or perhaps a 100 mesh screen works well in straining out most sand and grit. These types of spin-down filters are installed after the pressure tank.

Both the centrifugal sand separator and the screen filters have manual ball valves that allow you to flush out the sand.

If you use a lot of water or have a lot of sand in your water, it may require frequent cleaning, in which case an automatic flush valve can be installed.

These valves turn on for a few seconds and flush out the accumulated sediment and keep the sand trap clean.

A combination of different types of well water filters can also maximize performance and minimize maintenance.

If there are some sand and sediment such as clays, soil, or dust particles, a combination of a large mesh (60 mesh) spindown filter first, followed by a backwashing sediment filter, can eliminate most sediment and not require constant maintenance and filter changes.

The automatic backwash filters using turbidity filter media such as Chemsorb or Turbidex can filter down to the 3 to the 5-micron range and then backwash out the accumulated sediment to drain once or twice a week as needed.

In some cases, if there are very fine sediment less than 5 microns, a final stage dual-grade 1-micron depth filter is recommended. However, since most sediment is removed by the spin-down filter and sediment backwash filter, the cartridge lasts longer.

Do you have sediment or sand in your well water? If your well begins to pump sand or grit, get our free guide or call us for more information.